Capabilities

Chardon Tool

prides itself on being one of the few makers of

precision diamond tools

willing to challenge the laws of nature and physics.

We

accomplish this by working closely with our customers to

design tools to specifically meet their needs, no matter how

difficult it may be.

If you have need for an

uncommon tool or other diamond tool that

other manufacturers refuse to create, please visit our

contact page and speak directly with an

experienced Chardon Tool representative.

Chardon Tool Capabilities

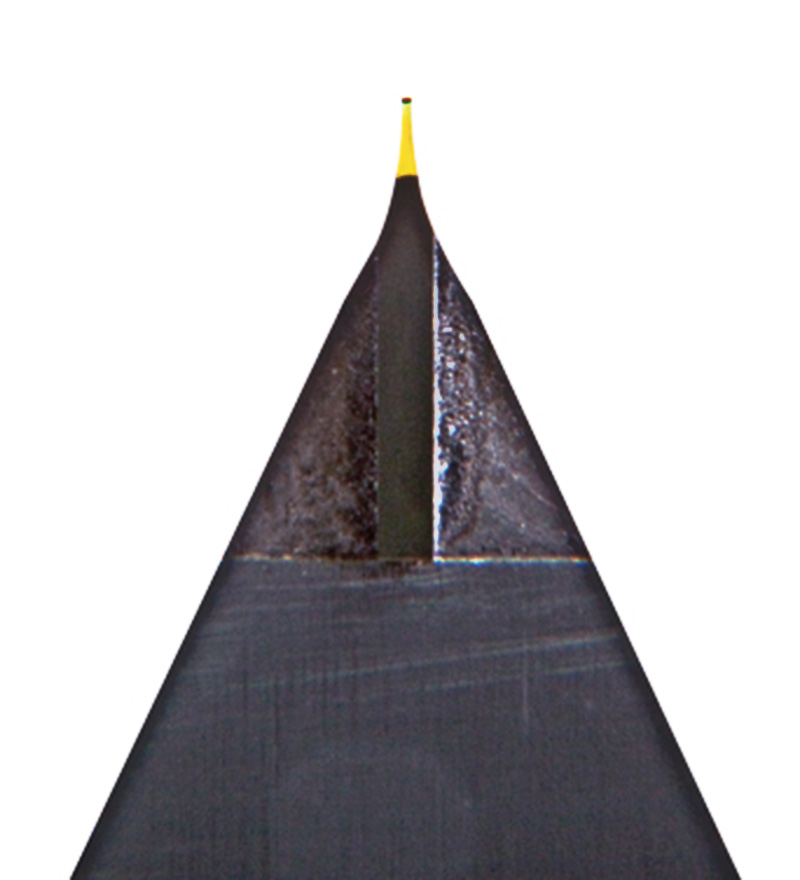

- Convex radii

- Concave radii

-

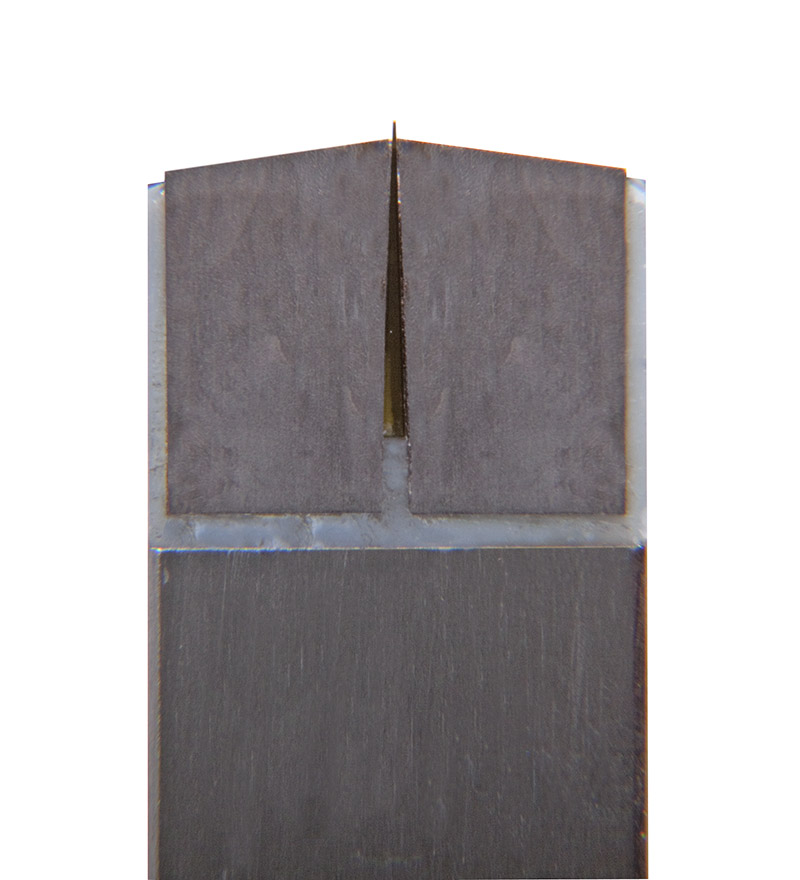

Conical clearance of up to 30˚, cylindrical clearance of up tp 45˚, and hybrid clearance

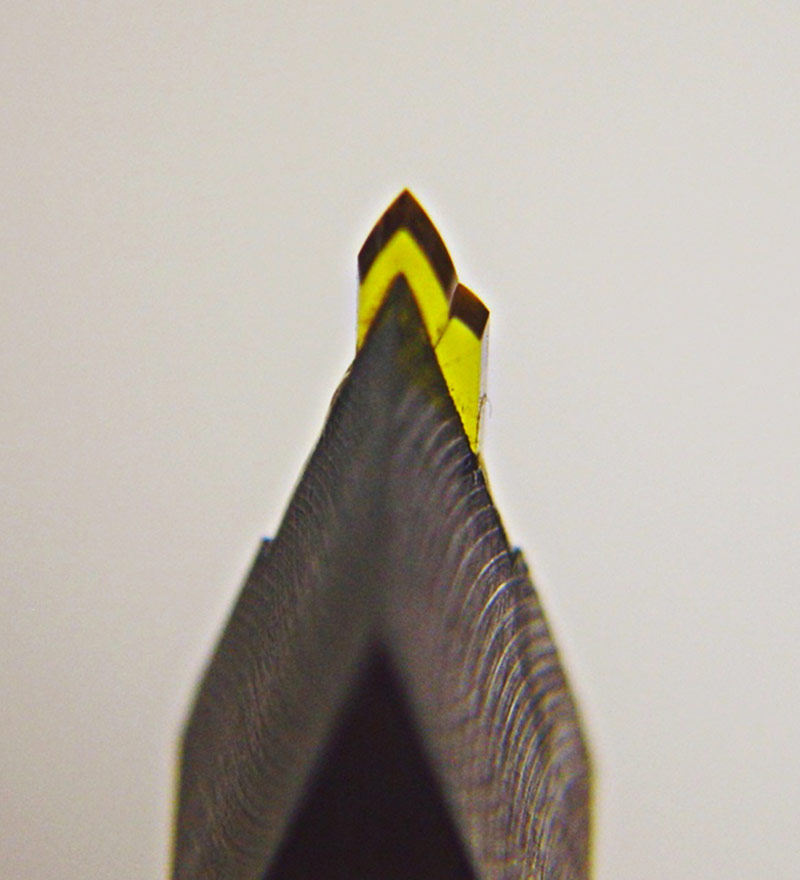

(a combination of conical and cylindrical clearances) - Included angles as small as 3˚

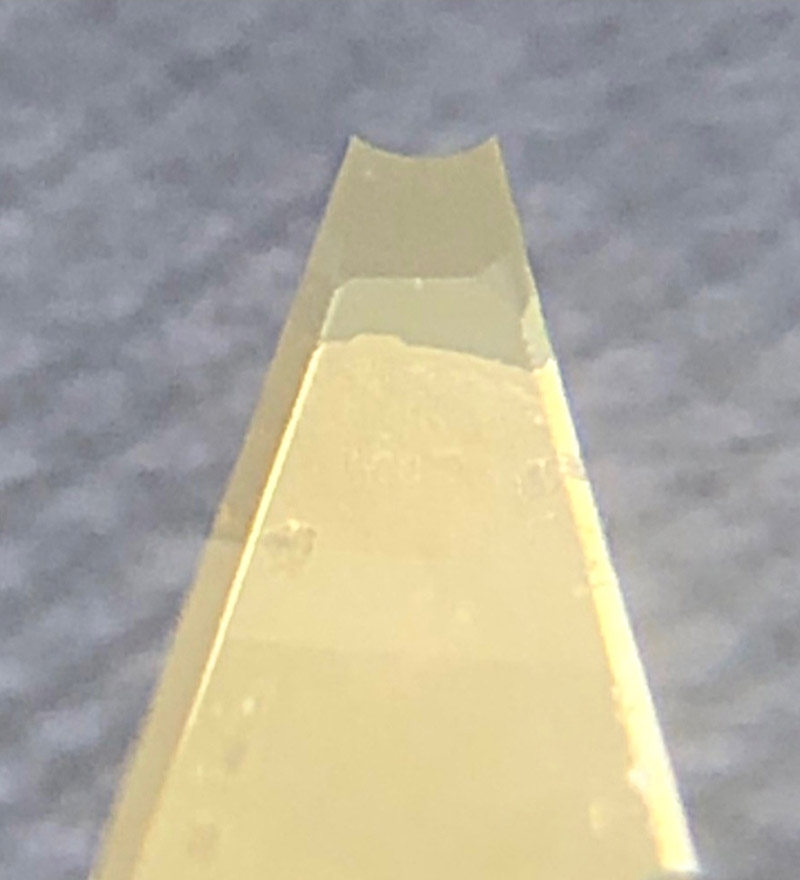

- Controlled edge waviness as low as 0.10 micron

- Radii from 1 micron to 100mm

- Measure and document radius sizes to 1 micron accuracy

- Measure and map the submicron form error of a diamond tool cutting edge using our proprietary, non-contact measuring technology

- Produce and measure included angles on diamonds to tolerances of a few arc minutes

- Diamond cutting edges defect-free at up to 1000x, or better, if needed. Defect-free can be achieved at 5000x, in some cases

- Check flatness of diamond cutting edges using microscope-based interferometry

- Produce diamond surfaces flat to 0.1 microns, with a roughness of less than 2nm Ra

- Aspheric shapes

- Very large diamond cutting edges, of up to 25mm

- Complex cutting edge shapes

- Ball end milling down to 25µm radii

- EXTREME ENDMILLSTM with high aspect ratios for a deeper reach with small cutting diameters