Diamond Types

The unique properties of

diamond

make it a leading choice for industrial tool use.

The

hardness

of diamond allows it to be ground and polished into very accurate and sharp cutting edges.

Check out our page with some

diamond facts

to learn more about what diamonds

Chardon Tool

uses in our wide array of tools.

Below, we will delve into different types of diamonds and other very hard cutting tool materials.

Natural

Natural diamonds are sought after by consumers for their beauty, ability to

refract light,

and their inherent uniqueness.

On the industrial side, diamond is sought after for its unique properties and their application to industrial processes.

We select only the best

natural diamonds for use in our tools to ensure we provide the highest quality products.

Our tools are less prone to breakage and achieve superior results in

surface finish

and

edge wear,

as a result.

This can be attributed to the knowledge obtained after years of experience and working closely with our customers.

Synthetic

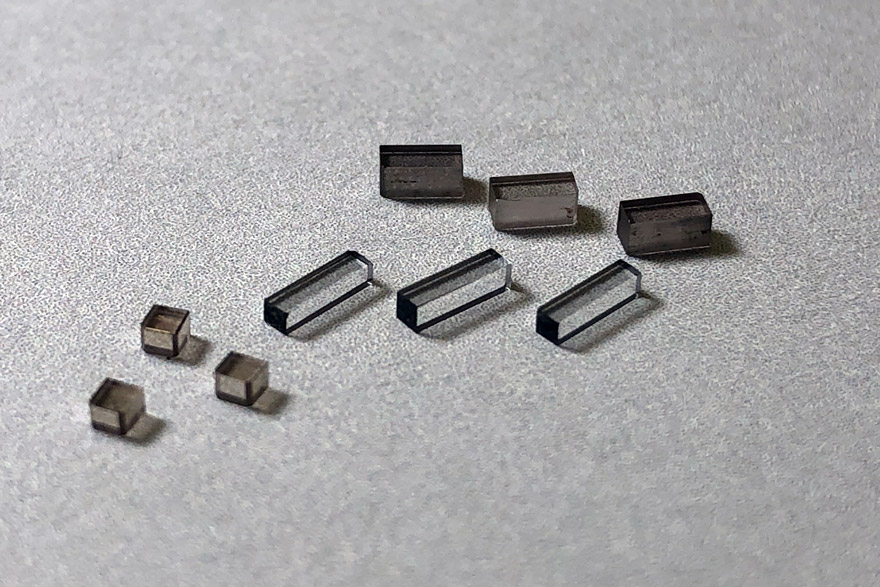

Single crystal

synthetic diamonds

are grown in a laboratory from a small diamond seed.

They have similar properties to natural diamond but often have superior

hardness,

thermal conductivity,

and

electron mobility

than natural diamond.

Synthetic diamonds can be manufactured in a variety of colors as well as completely colorless.

We work with

HPHT and CVD synthetic diamonds

to create our tools.

Also, many synthetic

diamond tools

can be

relapped

just like their natural counterparts.

Polycrystalline Diamonds (PCD)

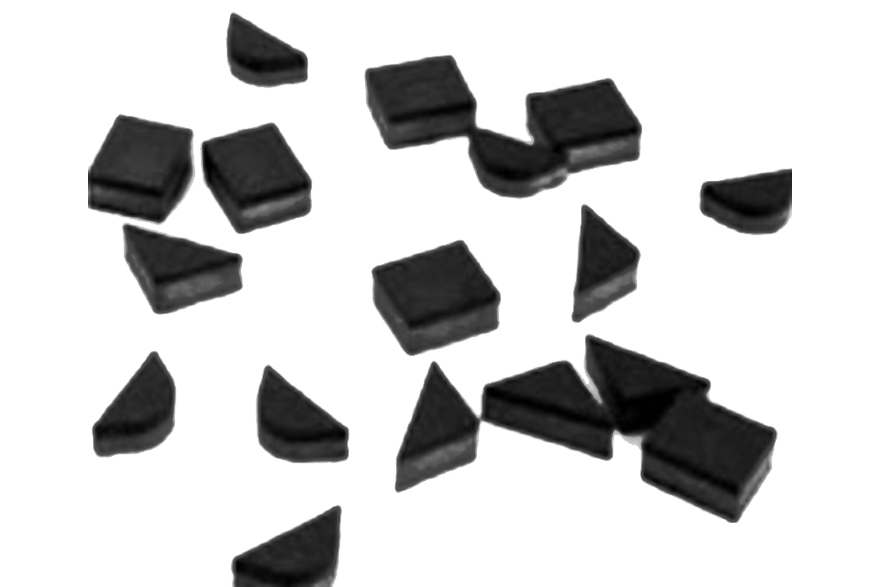

Polycrystalline diamond

(PCD) is composed of micron and submicron-sized diamond crystals that are bonded together under high heat and pressure.

A

PCD cutting tool

cannot produce the same form accuracy and

surface finish

as a

single crystal

diamond tool because of their

granular

nature.

PCD tools are often used for rough machining to near-net shape.

Final

machining

is typically completed with single crystal

diamond tools.

PCD tools are used to work on the

same materials

as single crystal diamond tools.

Cubic Boron Nitride (CBN)

Cubic boron nitride

crystals are the next hardest

cutting tool material

after

diamond.

Polycrystalline cubic boron nitride

(CBN) has a structure very similar to polycrystalline diamond (PCD).

A CBN cutting tool cannot produce the same

form accuracy and

surface finish

as a single crystal diamond tool because it is also

granular

like

PCD.

However, CBN is used to

shape many of the

materials that are

not diamond-friendly,

including hardened steel.

CBN tools are

typically used for machining to

near net shapes

before

final grinding or

polishing.